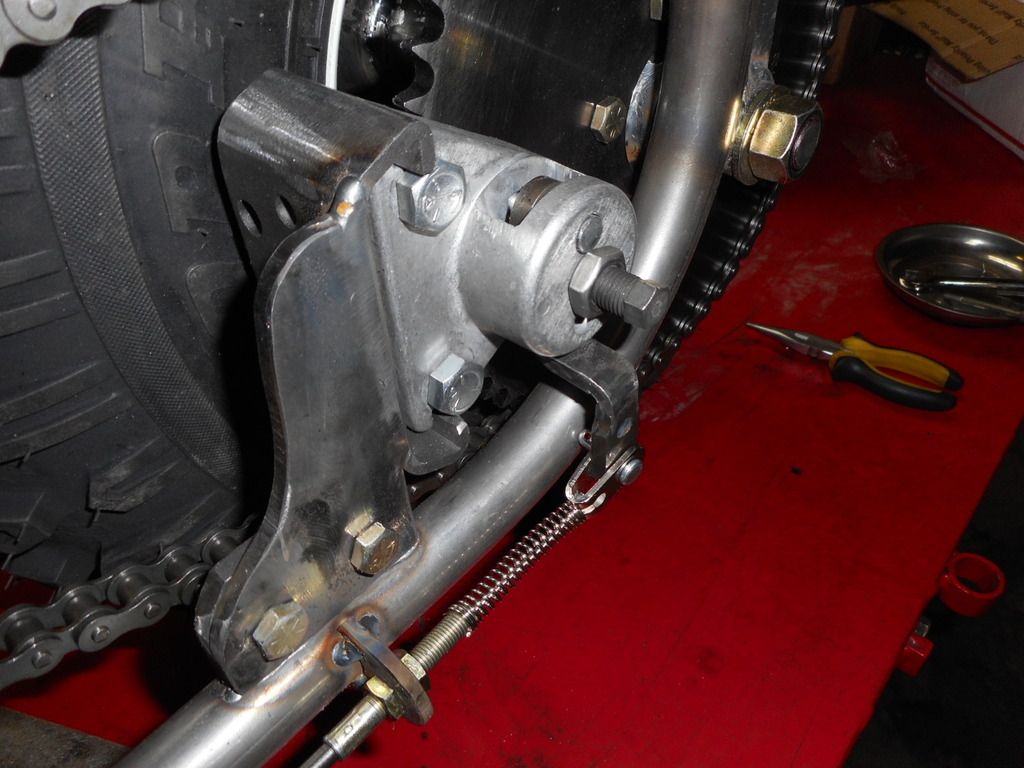

I had to make the brake lever off-set. Making the lever was easy enough.

However, once the lever was off-set, it twists when its pulled. The lever is designed to be pulled in a straight line, so the pin through the lever is really sloppy. I'm going to have make a better fit so that the lever twists less when pulled. The brake works really well and the "twisting" applies pressure just fine, but its sloppy.

First spin. Fun. I taped on the board after riding it with my ass on the tubes. No foot pegs yet so all of my weight was on my ass.

The fancy spring loaded idler I bought, ended up being pared down to just the roller. This works perfect.

I had a set of Harley peg mounts kicking around. I picked up a set of "take-offs" passenger pegs from the Harley shop for $10 a piece. I have not welded these on yet because of the tight space under the engine. I'll weld them on when the engine comes out.

The fenders are a real issue. After much humming and hawing, I decided that a widened version of a Princess Auto trailer fender would work fine. Bought two, split off centre and re-welded. So far so good...

I welded both inside and outside. I then used my belt sander to smooth the weld on the outside. My big mistake was I should have lightly hammered the weld so that it would stick up higher than the rest of the sheet metal. The two halves slightly curved down at the weld which meant the weld was in a (slight) valley. "No problem" thinks me; "this belts sander really works fast."

What I didn't know was that was reducing 14 gauge steel down to paper thin in spots. A crack developed and I thought I could just run a light bead over top. Nope. This was the second one that developed. The first one I patched. I'm putting this down to a learning experience. I won't use this one.

My quandary now is to start over or re-think. I like the look of no fenders. The 14 gauge steel is actually pretty heavy. However I did build this to ride it, and one mud puddle throwing mud all over my engine would spoil my day. I've thought about using the welded fender as a mold for making them in fiberglass. I actually took some Crazy Carpet plastic and my heat gun and tried to see if I could bend plastic over the welded fender. Paul says with a heat gun and a pair of oven mitts you can bend thin plastic to shape.

I'm going to work on the kick stand and think about the fenders..

Peace & Grease, Dennis