I know its not "vintage" but since I am a long standing club member and forum contributor, I figured many of you have seen my 883 Sportster on my lift for the last couple years with progress at a snails pace. This fall I had an epiphany moment when studying the wiring diagram, that I actually could figure it all out and probably even make it run. I have been going at it with some seriousness for a couple months now, and am hoping to also complete this bike for riding season in 2014. Not saying Father's Day ... just sometime in 2014.

Background: I bought the engine, wheels, forks, brakes, wiring, tank and fenders, even a windshield and saddle bags; everything but the frame in a package deal for $1500. Its all from a 2004 Sportster 883 which was the first year the engines were rubbermounted. Paughco introduced a rigid frame for the rubbermounted Sportster a few years ago, and I purchased one. I have been all over the web and have not seen a completed one yet. Hence the title to this thread; maybe I'll get some hits.

The first fab job was for the exhaust. The rubbermounted engine is allowed to vibrate fore and aft,, but not side to side. Because it moves, the exhaust has to be able to move with the engine. This rules out mounting the exhaust to the frame. The Paugcho rigid frame interferes with the stock exhaust mounting supports, so I had to cut, weld, cajole and otherwise modify it so that it would fit. I think I did this two winters ago.

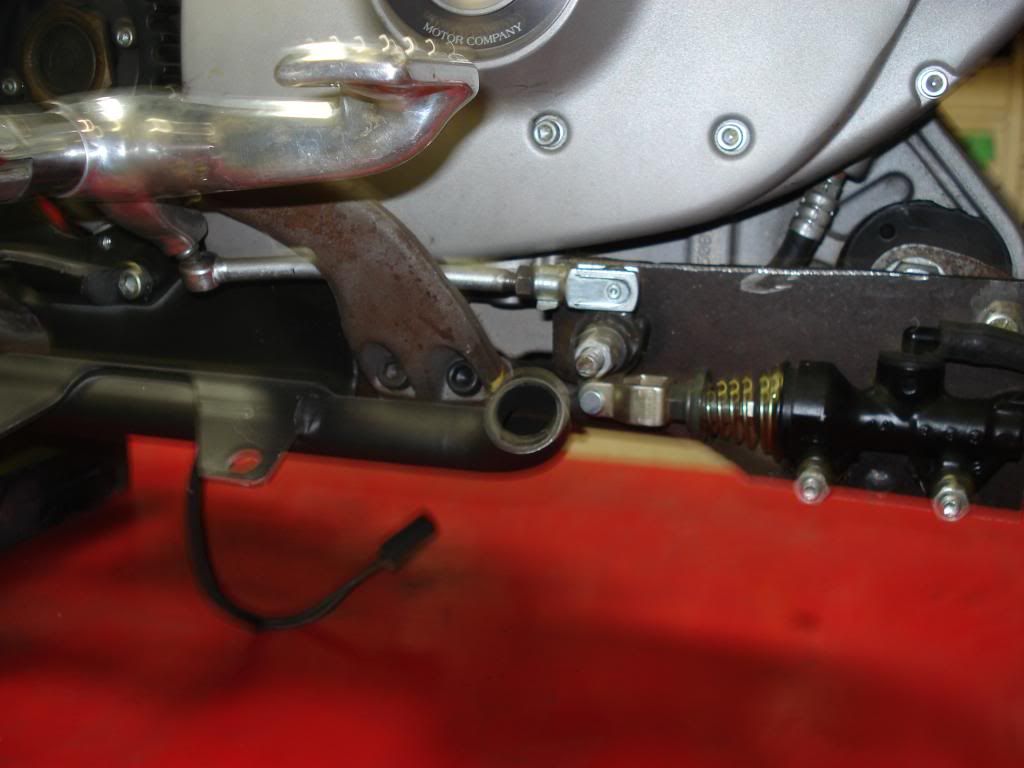

Last winter I was inspired only long enough to do the rear brake. The brake on the stock 883 pushes the rod aft to the master cylinder. There was no way that was going to work on this bike, so I fabbed up a mount for the master cylinder up front, and a linkage to make the rod push forward instead of aft.

The next two photos are of a brace I cut out. The brace interfered with where I want to mount the coil and the ignition switch; I want them in close to the stock position. My plan is to weld in a curved one after I have figured out where some of the other bits will get mounted.

The rear motor mount was not well thought out by Paughco. There is a small weldment with a threaded hole which I can only assume was supposed to be used for the rear mount, but it is not close enough or robust enough. I plan to cut it out and make my own. This is a photo of a male/female rod end I am trying to fit in. Jeff machined the spacer seen in the photo.

The oil tank was specified by Paughco for use with this frame and I bought it at the same time I bought the frame. I also bought their "mounting kit." The mounting kit is pretty because its chrome, but basically crap and the whole thing was pretty iffy. I cut off the mounts on the frame, ditched the chrome mounting kit, and am fabricating my own.

Peace & Grease, Dennis